With advancements in technology, burnishing techniques have become more precise and efficient. Manufacturers use machines to perform multiple varieties of burnishing processes, including diamond burnishing, roller burnishing, and multi-roll burnishing. In this blog, we will take a closer look at these various options for burnishing and polishing machines.

Diamond Burnishing

Among the various burnishing techniques, diamond burnishing stands out due to the precision it can deliver. As the name implies, diamond burnishing employs a diamond-tipped tool to polish the surface of a material. The tool features thousands of tiny micro-diamonds clustered onto it, delivering an impressively smooth finish.

Diamond burnishing is ideal for materials that require a high tolerance for finish and geometry, such as medical instruments, aerospace components, and automotive parts. This ability to deliver a high tolerance finish is due to the extreme hardness of the diamond tool, ensuring every minute detail is accounted for.

The use of diamond burnishing can also cut down on the time required for polishing operations, for it can achieve its optimal finish in just a few passes of the tool across a surface. This process reduces the need for sanding and grinding, thus saving time and money.

Roller Burnishing

Roller burnishing is another burnishing technique that involves using a spinning metal roller tool to polish a material's surface. Such rollers are outfitted with specialized abrasive inserts, in order to work as efficiently and effectively as possible upon the material. Roller burnishing can be useful for smoothing down grooves, depressions or bumps, correcting any surface irregularities.

Roller burnishing is a particularly popular technique among manufacturers because of how quickly it can work. A single pass of a roller burnishing tool across a surface is enough to achieve an excellent finish. This process can be used on various materials, including steel, aluminum, copper, and brass.

Multi-Roll Burnishing

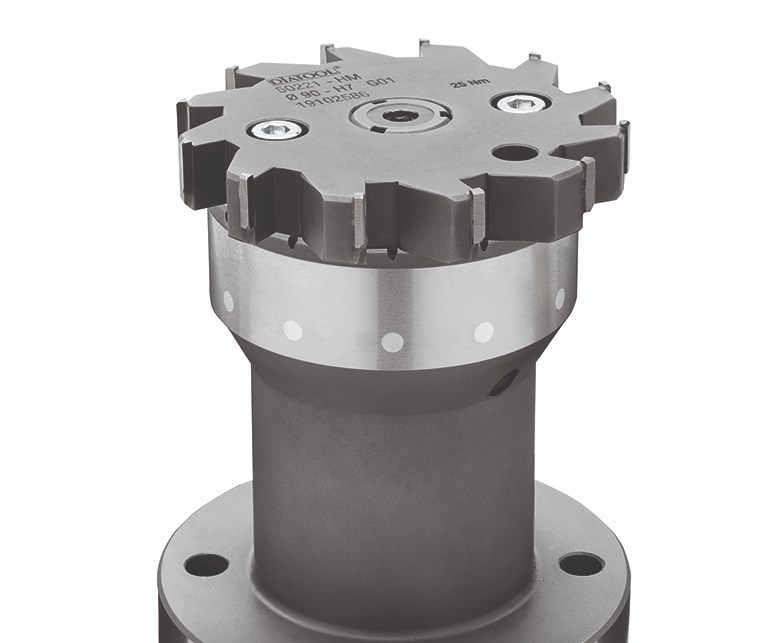

Multi-roll burnishing, similar to roller burnishing, also utilizes a roller tool to achieve a smooth and polished finish on a material's surface. However, in the case of multi-roll burnishing, there is more than one roller involved in the process. This technique is particularly useful for manufacturers looking to achieve precise and uniform finishes across long sections of material.

The multi-roll burnishing technique is often employed in applications such as tubing, shafts, and rods in which there is a need for a uniform finish. This technique can also be useful in the production of electronic components or medical parts, where the surface finish must be exacting for the device's functioning.

Polishing Machine

A polishing machine is another equipment that can be utilized in achieving smooth and polished finishes. Polishing machines come in various shapes and sizes and can be applied to a wide range of materials, including wood, plastics, metals, and glass.

Polishing machines use a circular blade, powered by a motor, to rotate and polish the material. The type of blade employed in the machine will be determined by the material to be worked on.

Conclusion

In conclusion, burnishing and polishing are essential procedures in the manufacturing of high-quality products with a good finish. Diamond burnishing, roller burnishing, multi-roll burnishing, and polishing machines are some of the options available for burnishing and polishing operations. Manufacturers should choose the most appropriate option based on their specific needs.

At Monaghan Tooling, we offer different types of burnishing and polishing machines for a wide variety of applications. Our burnishing machines can achieve a mirror-like finish while reducing the need for additional finishing processes. Get in touch with us today for your all your burnishing and polishing needs.