- Power(W):

- 3HP

- Dimension(L*W*H):

- 1050*400*850mm

- Weight:

- 95kg

- Warranty:

- 1 Year

- After-sales Service Provided:

- Free spare parts, Video technical support, Online support, Overseas third-party support available

- Applicable Industries:

- Building Material Shops, Machinery Repair Shops, Manufacturing Plant, Construction works

- Condition:

- New

- Automatic Grade:

- Semi-Automatic

- Place of Origin:

- Shanghai, China

- Brand Name:

- JSFLOORSYSTERM

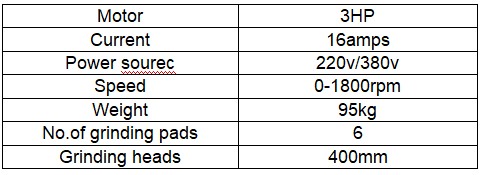

- Voltage:

- 220V/380V

- Certification:

- CE SGS ISO9001

- UNIQUE SELLING POINT:

- Long lifetime

- Current:

- 16amps

- Speed:

- 0-1800rpm

- No.of grinding pads:

- 6

- Grinding heads:

- 400mm

Introduction of planetary concrete floor grinder

JS concrete grinder floor polishers are ideal for floor surface preparation and renovations. Levels unevenconcrete surfaces and removes paint, traffic lines, fibre glass, expoxy and adhesives. ideal for smoothing out rough concrete finishes caused by rain splatter and poor trowelling.

Our concrete grinder floor polishers are ideal for:

Removing adhesive residues, mastics, epoxies, urethane, paint and thick coatings

Smoothing or flattening concrete slabs–including curled expansion joints

Removing surface imperfections and contaminants

Our concrete grinder floor polishers use horizontally rotating disks to level, smooth and clean concrete surfaces.

The equipment is specifically designed for the rigors of commercial/contractor use, with powerful motors for increased air flow, heavy duty filters, and components that are protected from dust and debris for longer life.

Our machines’ HEPA filtered vacuums offer a virtually dust-free and comfortable work environment. Particulate and dust can get everywhere, so we set up with floor wands and magnetic brooms, as well as negative air, to create an environment free of contaminants. It’s a safer, cleaner way to work and it maximizes our productivity.

Planetary grinder applications

JS flooring machines are available in different sizes and versions depending on your needs and demands

from edge grinding machine S320 , to professional epoxy floor grinder JS400 ,

from heavy duty planetary grinder S650 to Ride on remote control floor grinder D1200,

Used for grinding and polishing marble, granite and concrete floor, etc

Combined with our dust extractors , floor scrubber and diamond tools,

we offer a complete system which guarantees that you finish the job with the best result and economy.

Welcome to be our long term partner and come to our factory:

No. 1333, Xinlong Rd., Minhang District, Shanghai, China (Mainland).

Feature

1:220V, one button start, compact and convenient, with little abrasive wear.

2:Can be adjusted to level manually, easily replace metal pads or resin pads.

3:Professional open dust cover, for grinding and polishing every floor edge corner.

4:High rotation speed and cutting efficiency, good leveling effect.

5:Applied for floor polishing, epoxy removal of ground corner, etc.

6:Motor direct drive, new vibration reduction system, and aluminum alloy head, avoid of malfunction.

7:Folding handle, lightweight body, and easy to carry personally.

8:Can be transported in small car

9:Equipped with V2 industrial vacuum cleaner, can achieve dust free grinding and polishing.

Parameter of planetary concrete floor grinder

Packing & Delivery

For Packing

We usually use custom hard wooden case for our concrete floor grinder

For Shipping

Normally deliver by sea,If in a hurry, air delivery is also ok.

ertificate